Key points of M16 connector terminal crimping technology

time2025/08/22

- Crimping is a critical process for ensuring a secure and reliable connection in M16 circular connectors, widely used in industrial automation, robotics, and harsh-environment applications. Incorrect crimping can lead to electrical failures, signal loss, and safety hazards.

Crimping is a critical process for ensuring a secure and reliable connection in M16 circular connectors, widely used in industrial automation, robotics, and harsh-environment applications. Incorrect crimping can lead to electrical failures, signal loss, and safety hazards.

At Connoder, a global provider of industrial connector solutions (About Us), we combine precision engineering with strict quality control to guarantee optimal crimp performance for every M16 connector we produce.

Why Crimping Matters in M16 Circular Connectors

- Gas-tight electrical connection to prevent corrosion.

- High vibration resistance, suitable for industrial environments.

- Mechanical durability for long service life.

Standards like DIN EN 60352-2 define the benchmark for crimp quality. Connoder strictly adheres to these standards in every production line.

Key Steps for Proper M16 Connector Crimping

Step 1: Wire Preparation

Strip the wire to 4 mm length (avoid damaging strands). Keep conductor strands clean and aligned.

Step 2: Contact Insertion

Insert stripped wire into the M16 contact barrel fully. Ensure correct positioning for mechanical stability and electrical continuity.

Step 3: Tool and Die Selection

Use the correct crimping tool and die based on wire cross-section and connector type. Connoder recommends using precision-calibrated tools for consistent results.

Step 4: Crimp Execution

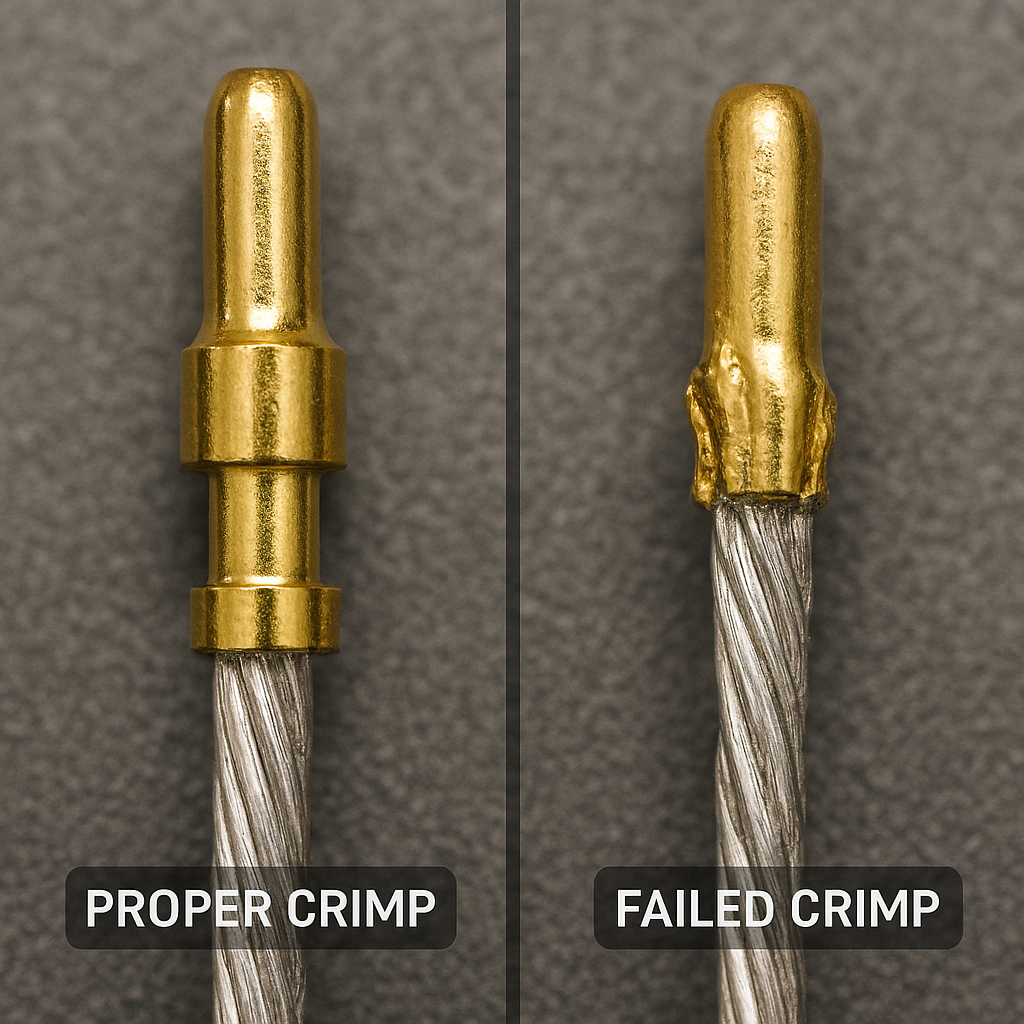

Apply steady force using the appropriate tool setting. Avoid under-crimping (weak mechanical hold) or over-crimping (damaged conductor).

Step 5: Quality Testing

Perform pull-out test for tensile strength. Check crimp height and contact resistance. Validate against DIN EN 60352-2 standards.

Common Mistakes to Avoid

- Incorrect wire strip length or frayed strands.

- Using mismatched contact and tool.

- Skipping mechanical or electrical testing.

Connoder’s Advantage: Our assembly line uses automatic calibration tools and in-process quality control (IPQC) to eliminate these errors.

Connoder’s Expertise in M16 Crimping Solutions

- Over 10 years of experience in industrial connectors.

- ISO-certified manufacturing, ensuring product reliability.

- Customization services for M16 connectors with IP67/IP68 sealing.

- Rapid prototyping: 1-day drawings, 15-day samples, and flexible MOQs.

Crimping vs. Soldering — Why Crimping Wins

- Faster installation and better repeatability.

- Superior vibration and corrosion resistance.

- Easier field maintenance compared to soldering.

Download Technical Resources

Connoder provides detailed datasheets and crimping guides for our M16 connector series.

Conclusion

The key points of M16 connector terminal crimping technology boil down to precision, tool selection, and testing. By following industry standards and partnering with Connoder, you ensure a safe, durable, and efficient connection every time.